Polyether defoamer is a kind of non-ionic surfactant, which has excellent defoaming and foam inhibition function, non-toxic, insoluble in water, soluble in organic solvents, can be used alone, can also be used as emulsion.

Polyether defoamer is one of the most important varieties of defoamer products, with non-toxic, odorless, non-irritating and easy to disperse in water and other characteristics, in addition to general industrial applications, but also can be used in food, fermentation, cosmetics and medicine and other industries, is silicon defoamer can not be replaced.

Polyether defoamer can be divided into polyol type, fatty acid ester type and amine ether type according to the different initiators used in synthesis, among which polyol type and fatty acid ester type are widely used. The production of polyether defoamer in China began in 1969 and was first applied to antibiotic fermentation. These products mainly include GP type glycerol polyether, GPE type polyoxyethylene (polyoxypropylene) ether and PPG type polypropylene glycol.

Performance

1, good dispersion, dynamic defoaming, defoaming speed, strong foam inhibition performance

2, does not contain minerals, is conducive to environmental protection

3, excellent effect in a wide range of temperature and pH

1. Effect of different initiators on the performance of polyether defoamer

2. The effect of different block methods on the performance of defoamer

3. The effect of different epoxy chain length on defoaming properties

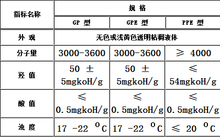

Specifications and indicators

Polyether defoamer

Polyether defoamer series can be widely used in industry, the monosodium glutamate, yeast, citric acid, itaconic acid, xanthan gum and other fermentation process of defoaming, can also be used in chemical, textile, printing and dyeing, paint, coating, paper and other industries, the effect is remarkable. The product conforms to the national hygienic standard.

How to use

1, should use a small amount, the principle of many times to add defoamer.

2. This product can be heated and disinfected with the original solution and fermentation base material into the tank, or it can be prepared into water emulsion and directly sterilized by steam, and then "fed" into the tank for defoaming.

3. The defoamer emulsion preparation tank has a mechanical stirring device to make the defoamer fully dispersed and uniform to achieve the ideal defoaming effect.

Packaging and storage

1, this product is packed in 25 KG or 200 KG galvanized iron drum, can also be packed according to user requirements.

2, storage and transportation: waterproof, sunscreen, sealed storage at room temperature, not mixed with toxic substances.