Silicone rubber mold is a silicone room temperature two-component mold glue (Room Temperature Vulcanization), referred to as RTV, commonly known as Silicon Licon. It is a two-component compound. The A component contains the crosslinker and the B component contains the catalyst. During the packaging process, the crosslinker must be separated from the catalyst. Its vulcanization is carried out at room temperature, as long as the two components are mixed in a certain proportion (the specific proportion can be determined according to the operation time and product performance), the two component compounds undergo cross-linking reaction to form a flexible and elastic colloid, so it is suitable for Polyster resin (POLYSTER) epoxy resin (EPOXY), Pu foam resin, gypsum, cement, candles, electronics and other craft factories, toy factories, electronics factories, lighting factories, screen printing factories, candle factories, production of decorative crafts and replica products, manufacturing molds

Building decoration materials, handicrafts, imitation mahogany furniture, precision casting, high-frequency embossing, cultural relics reproduction, gypsum board production and other industries of mold-making materials

Nature

(1) Good chemical stability, non-toxic and non-corrosive;

(2) Good fluidity, can automatically fill the mold;

(3) It can control the vulcanization speed, vulcanization at room temperature and pressure, which is easy to operate;

(4) Good mold release;

(5) Strong simulation, realistic ornamentation;

(6) The mold making speed is fast, and the mold can generally be made within 20h.

Material

Mold silicone rubber is generally composed of base rubber, crosslinking agent, catalyst, filler, etc.

The base rubber is 107 silicone rubber, called hydroxyl-terminated dimethicone.

This mold silicone rubber can be cured at room temperature, has good flowability, no deformation, and only tiny line shrinkage.

The crosslinking agent is ethyl orthosilicate. The amount of crosslinking agent added has obvious effects on the curing time, tear strength and elongation of silicone rubber, and practice has proved that the amount of crosslinking agent should account for 5% (mass fraction) of the base rubber.

The catalyst is dibutyltin dilaurate. The amount of catalyst added is directly related to the curing time, and it should not be too much, generally 1%~2% (mass fraction).

Fillers include talc, quartz powder, silica. Generally, talcum powder is used as filler. When silica is used as a filler, it has significantly improved mechanical strength, tear strength and uniformity.

Mold-making process

Take the manufacture and reproduction of Maitreya Buddha mold as an example to illustrate the rubber mold manufacturing process.

(1) Select the bottom opening as the positioning part, turn it over to the cavity and fill it with plaster, its height is about 30mm higher than the bottom, and dig out the pit for later positioning.

(2) Paste plasticine. Paste a layer of rice paper on the surface of the utensil, and then evenly paste 5mm thick plasticine on the surface.

(3) Plaster by mold. In order to support and fix the RTV mold and prevent its elastic deformation, the gypsum mold is first made outside the mud layer. Make plaster images one by one according to its approximate parting surface, pay attention to the positioning between plaster molds, gypsum slurry is gypsum: water = 1:1.

(4) RTV molding mold production. The plaster is molded in reverse order, plasticine is removed, cleaned up, and the parting agent is applied to the utensils and plaster molds separately, and then the mold is closed.

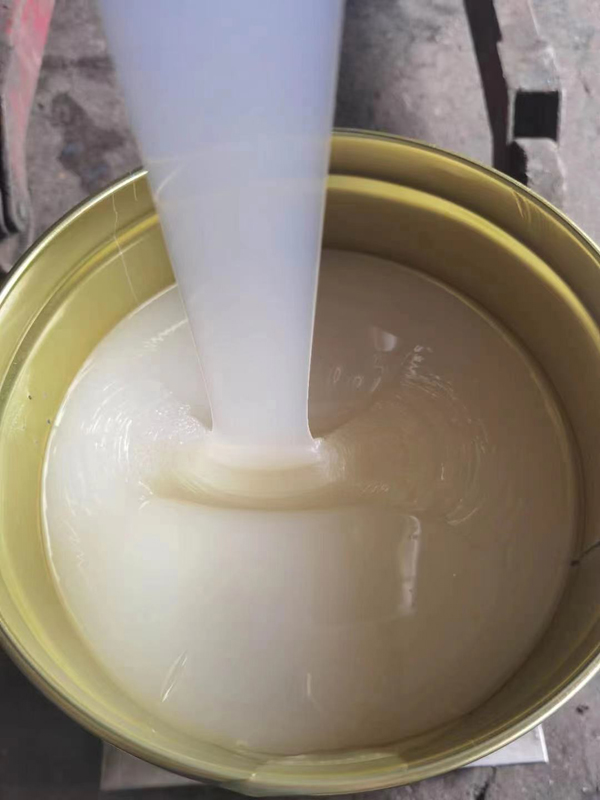

At the same time, the components of RTV are weighed in proportion and stirred thoroughly after mixing. Since during the stirring process, RTV and ethyl orthosilicate react under the action of accelerator organotin to produce low molecular weight alcohols, and when pouring silicone rubber, pores are generated on the molding mold body, so it must be degassed under reduced pressure, and one strand is carried out in a closed container with a vacuum degree of 100mmHg for about 5min.

The silicone rubber with depleted bubbles is injected into the cavity of the mold, and the room temperature cures for about 24h.

Take off the plaster mold, cut it with a razor according to the expected parting line, carefully peel off the silicone rubber from the utensil, remove the utensil, and then close the silicone rubber mold with the plaster mold as it is, and the silicone rubber mold is made.